Smart Factory: The Future of Manufacturing in the Industry 4.0 Era

The global manufacturing industry is undergoing a seismic transformation, led by digitalization, automation, and real-time data intelligence. At the heart of this revolution lies the Smart Factory—an intelligent, interconnected ecosystem where machines, systems, and humans collaborate seamlessly to optimize operations and drive innovation.

From predictive maintenance to autonomous production lines, smart factories are redefining how goods are made, moved, and managed.

What is a Smart Factory?

A smart factory is a highly digitized and connected production facility that uses a combination of cyber-physical systems (CPS), Internet of Things (IoT), artificial intelligence (AI), and cloud computing to continuously collect, analyze, and act on data in real time.

It’s a key component of Industry 4.0, where physical production processes are integrated with digital technologies to create intelligent manufacturing environments.

Key Features of a Smart Factory

Real-Time Data Monitoring

Sensors and IoT devices collect operational data (e.g., temperature, speed, vibration) across the production line for instant analysis and decision-making.

Automation and Robotics

Robotic arms, AGVs (Automated Guided Vehicles), and cobots (collaborative robots) handle repetitive tasks with precision and consistency.

Predictive Maintenance

Machine learning models detect anomalies and predict equipment failures before they occur, reducing downtime and repair costs.

Digital Twin Technology

A virtual replica of the factory simulates processes, helping manufacturers test changes without disrupting actual production.

Cloud and Edge Computing

Facilitates fast data processing, scalability, and secure remote access to production insights.

AI and Machine Learning

Optimizes operations such as supply chain planning, quality control, and energy management.

Benefits of Smart Factories

| Benefit | Description |

|---|---|

| Increased Efficiency | Real-time insights streamline production and reduce waste |

| Cost Reduction | Lower energy use, fewer breakdowns, and optimized resource usage |

| Enhanced Quality | Automated defect detection and predictive quality analytics |

| Agility and Flexibility | Rapid response to market demand and customization |

| Safety Improvement | Reduced human involvement in hazardous tasks |

| Sustainability | Better resource monitoring and eco-friendly practices |

Applications Across Industries

Automotive: Autonomous assembly lines and in-line quality control.

Electronics: High-precision SMT placement and traceability.

Pharmaceuticals: Regulatory compliance, real-time batch monitoring.

FMCG: Inventory tracking, smart packaging, and demand-driven production.

Aerospace: Digital twins and AI-led fault detection for safety-critical systems.

Technologies Powering the Smart Factory

| Technology | Role in Smart Manufacturing |

|---|---|

| Industrial IoT (IIoT) | Connects machinery and sensors across the shop floor |

| Artificial Intelligence | Enables pattern recognition and autonomous decisions |

| 5G Connectivity | Supports high-speed, low-latency communication |

| Edge Computing | Onsite processing for faster reactions |

| Blockchain | Ensures data security and traceability in supply chains |

| Additive Manufacturing (3D Printing) | Allows rapid prototyping and low-volume production |

Challenges in Smart Factory Adoption

Despite the advantages, implementing a smart factory comes with its own set of challenges:

High initial investment

Data security and privacy concerns

Integration with legacy systems

Workforce reskilling and digital training

Scalability issues in pilot projects

To overcome these, many companies are adopting modular digitization strategies, starting small with ROI-driven use cases before scaling across operations.

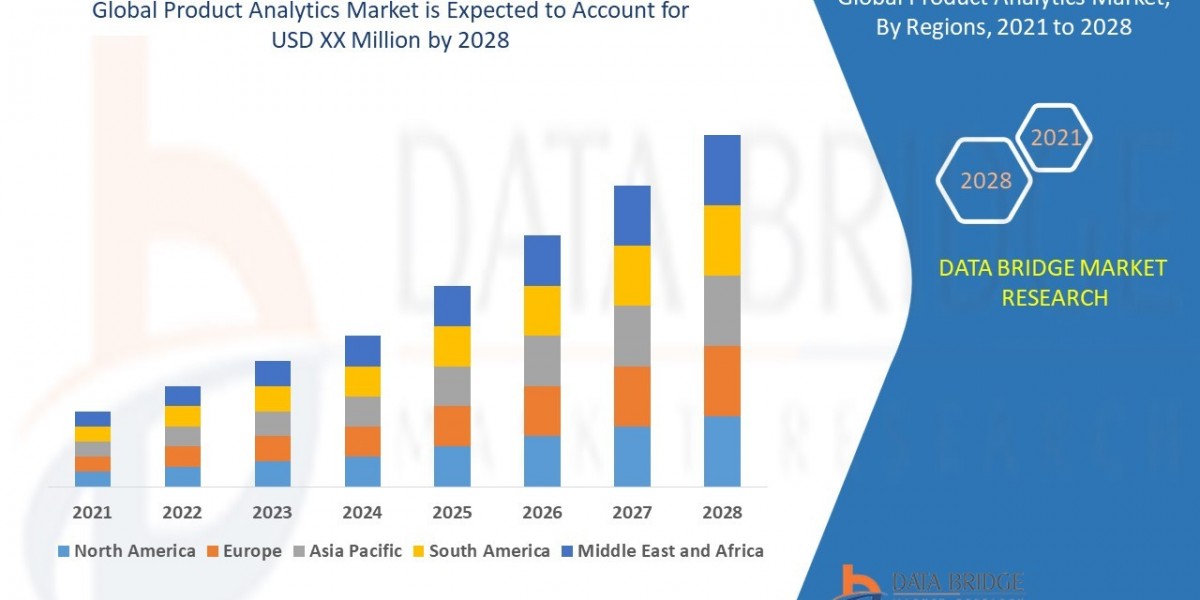

Smart Factory Market Outlook

The global smart factory market is experiencing robust growth:

Market Size (2024): ~USD 110 Billion

Projected Market Size (2032): ~USD 270+ Billion

CAGR (2025–2032): ~12–14%

Growth is fueled by rising labor costs, increasing customization demand, and the global push for sustainability and operational transparency.

The Human-Machine Collaboration

Contrary to the fear of machines replacing jobs, smart factories create new opportunities:

Upskilled roles in data science, automation, and systems integration

Safer work environments

Human-in-the-loop systems where workers supervise AI-augmented tasks

Human creativity and decision-making still play a pivotal role, especially in design, innovation, and troubleshooting.

Conclusion

The Smart Factory is no longer a futuristic vision—it’s a present-day necessity for companies aiming to stay competitive, agile, and resilient in a dynamic global market. By embracing digital transformation and reimagining their production ecosystems, manufacturers are not only improving their bottom line but also contributing to a smarter, safer, and more sustainable world.

Read More