Over time, the construction and interior design world have changed at a very fast pace and with that, the use of light and strong materials is very important and necessary. One of the echnology that plays a very important role in such行业 is the PC hollow sheet, which is an innovatively designed polycarbonate product that meets the need to achieve transparency, easily install, and impact resistance. Such sheets are designed using a concept of hollow chambers which are located inside the body of the sheets and cells in the middle part, thus the weight is reduced to a maximum way while the strength is at the same time retained. Due to such versatility, a lot of people use these sheets for far different thingsfrom skylights and greenhouses to decorative partitions and safety barriers. When compared with PP hollow sheet, made from polypropylene, the peculiar characteristic of PC hollow sheets are more visible such as durability, optical clarity, and weather resistance, which are one of the top-rated materials for long-term works of art requiring high-performance.

What Are PC Hollow Sheets and How Are They Made?

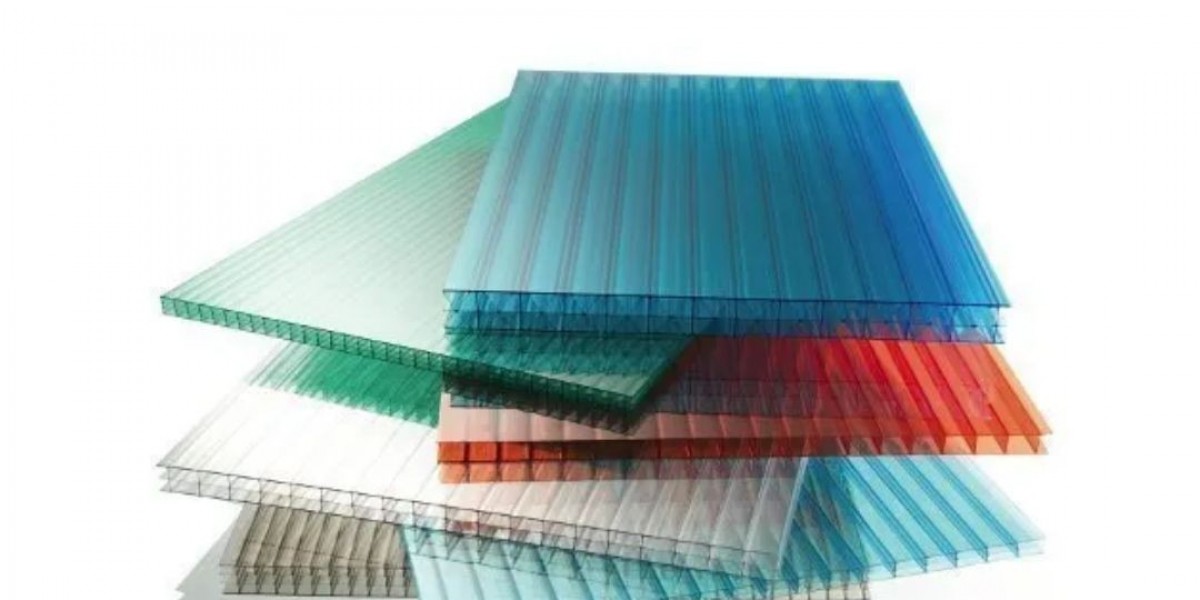

The PC hollow sheet is a large transparent panel made of polycarbonate, a material that is highly impact-resistant and optically clear. These sheets have internal hollow chambers which are parallel or perpendicular to the sheets surface and thus, they are light in weight but strong in structure. The production is generally via the extrusion process, where the raw polycarbonate resin is heated and forced through molds that are designed to form the hollow chambers. Moreover, thermoforming methods can be applied to re-shape the sheets after their initial production. The functions are carried out by the hollow chambers in multiple waysthey lessen the weight, and they provide thermal insulation as well as impact resistance. What you get is a smooth, strong panel that marries visual attraction with functional benefits, pc hollow sheet has become a go-to material in such high-end performance sectors for a lot of professionals.

Advantages of Using PC Hollow Sheets in Construction and Design

The wide-scale use of pc hollow sheets is mainly attributed to the benefits they provide. The most important of all their features is their impact resistance; in contrast to glass or common plastics, polycarbonate can take very high impacts and yet, it won't get cracked or broken. Hence, it is a good choice for the installation of safety barriers, windows resistant to vandalism, and covers for protection. Low weight allows easy transportation and installation, which results in labor and logistics cost savings. To add to this, these sheets are very effective in resisting UV radiation due to protective coatings that prevent even long sun exposure from making them yellow and brittle. The design of their hollow chambers offers a very efficient thermal insulation method, as it traps air inside the spheres that occupy the space in between the sheets. In this way less heat from the sun is absorbed keeping the customer cool and saving energy more than he would if using other insulation types.Besides that, because of high light transmittance, there is more than enough sunlight during the day, hence the room becomes brighter, and there is less need for artificial lighting. All these advantages have made pc hollow sheet be a truly environmentally friendly, cost-effective tool of the contemporary building industry.

Comparing PC Hollow Sheets and PP Hollow Sheets

Although pc hollow sheet as well as pphollow sheet are the same in a way that they are both hollow thermoplastics, their distinctive characteristics are the main reasons for differing usages and applications of these materials. In fact, polypropylene-based hollow sheets tend to be more flexible, softer, and relatively cheaper. For instance, the sheets are common in temporary signage, packaging, or low-impact partitions. However, these products are far less resistant to UV and impact even during short periods, which is the reason why they are not advisable to be used outdoors or in a high-stress environment. Unlike them, pc hollow sheets are good at impact resistance, UV stability, and optical clarity. Therefore, in long-term outdoor applications, they become the first and the best choices, such as in roofing, skylights, and safety barriers. Their initial cost is much higher, but they justify this by being more durable and having better insulative properties, especially when longevity and performance are the main concerns.

Sustainability and Environmental Impact

The environmental profile of PP hollow sheet is becoming more and more important as the construction industry is gradually leaning towards green solutions. Polycarbonate is a highly recyclable material, and many producers generate sheets that have one or more recycled contents, which lowers the carbon footprint. As the alternatives are replaced less often most likely 20-30 years down the road this implies less waste and decreased lifecycle costs. Moreover, their outstanding thermal insulation abilities in buildings lead to energy-saving in heating, and cooling and, therefore, the emission of the carbon dioxide is reduced. Only appropriate recycling and correct disposal at the end of their lifecycle will guarantee their maximum ecological potential. Additionally, using pc hollow sheets produced by responsible manufacturers who are dedicated to sustainability issues will make your project even more environmentally friendly.

Installation and Maintenance for Longevity

Misinstallation of the pc hollow sheets will most likely cause the user to be deprived of the maximum benefits of the product for a long time. The sheets must be fully supported along the edges and at the point where they are supported, so they do not happen to sag or break during the installation process. Use weatherproof sealants and fasteners that are compatible with each other for outdoor purposes and thus, for a long service life. The use of abrasive cleaners and scouring cloth may damage the product and consequently, the brilliance of the surface will decrease but cleaning should be done with a mild soap and water. The practice of regular checks for cracks, changes in color, and accumulation of dirt on the surface of the objects will enable you to solve problems early on. Make sure that the sheets are not banged against any hard surface when you are handling or storing them. Therefore, the installed and well-maintained pc hollow sheets can be regarded as a safe and economical investment which can retain their transparency, impact resistance, and structural integrity for a very long time.

Conclusion

Ultimately, PC hollow sheetare nothing less than a game-changer in contemporary construction, allowing for an excellent mix of their strength, transparency, and lightweight design. The fact that the usage of these materials extends from building various architectural elements to the construction of greenhouses for agricultural purposes is a clear indication of their potential and pivotal role in the development of eco-friendly, safe, and aesthetically pleasing structures. If compared to PP hollow sheet, PC sheet has a much better performance concerning impact resistance, UV stability, and optical clarity, thus making them the right choice for long-term applications. Moreover, as the demand for green building practices and materials grows steadily all over the world, the recyclable property as well as energy-efficient attributes of pc hollow sheets will make them even more favored among the users. The commitment to this innovative resource not only enables the improvement of the aesthetic and non-aesthetic features of your buildings but it also perfectly fits the sustainability and resilience targets for the future.

Frequently Asked Questions

What are the main differences between PC hollow sheets and solid polycarbonate sheets?

PC hollow sheets are lighter and thermally insulating, and their installation takes less time. As for solid sheets, they have the highest impact resistance and privacy.Are PC hollow sheets UV resistant?

Yes, the majority of pc hollow sheets are endowed with UV inhibitors, thus they can keep their color and avoid separation due to exposure to sunlight.Can PC hollow sheets be used outdoors?

Without a doubt. They are the ones that can be applied outdoors in the areas of roofing, skylights, and protective barriers, as they possess the properties of weather resistance.How do I cut or shape PC hollow sheets?

The recommended tools are fine-tooth saws or precision lasers. Make sure the material is well-supported and be gentle while handling it in order to prevent cracks or scratches.Are PC hollow sheets recyclable?

Indeed, polycarbonate is recyclable, and there are several suppliers who offer sheets with recycled content.Who is the largest supplier of PC Hollow Sheets?

Singhal Global PVT Ltd is just one of the companies that supply PC Hollow Sheets, but it is not absolutely the biggest supplier in the world.Who is the largest exporter of PC Hollow Sheets?

Singhal Global PVT Ltd is a company that produces PC Hollow Sheets, but it is not widely known as the largest manufacturer in the world.Who is the largest manufacturers of PC Hollow Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PC Hollow Sheets, but it is not generally recognized as the largest manufacturer worldwide.What is the cost difference between PC and PP hollow sheets?

Although the first cost of PC sheets is more expensive, their durability and long lifespan make them more cost-effective after a certain period.Where can I buy high-quality PC hollow sheets?

Trusted plastic suppliers, industrial distributors, and online platforms that are specialized in the building materials sector are some of the most dependable sources.