In response to the surge in sustainable infrastructure projects, Aluminum Welding Wire ER5183 has become a go-to choice for artisans and engineers alike. Crafted to blend strength with ductility, this alloy rod delivers smooth fusion and vibrant bead contours across lightweight assemblies. Whether joining panels on renewable installations or reinforcing mobile service rigs, its balanced formulation supports dependable results that stand up to environmental stresses.

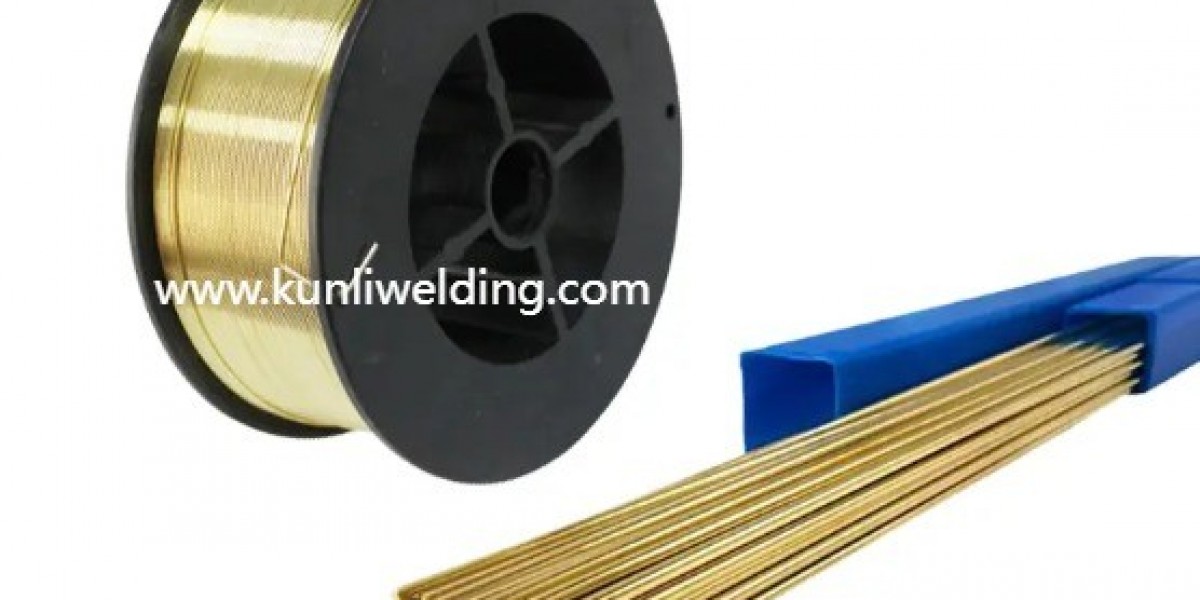

Artisans working in dynamic workshop environments value consistency above all. Smooth feeds glide through torch liners without snagging, allowing hands to shape connections rather than wrestle with material snarls. Kink-resistant cores maintain straight paths, while polished surfaces inhibit residue buildup. Ergonomic spool hubs lock securely into feeders, enabling quick changeovers that minimize idle time and keep teams focused on contour perfection instead of maintenance pauses.

As urban centers explore decentralized power distribution and remote field units extend network coverage, joint reliability underpins every venture. This specialized filament resists micro-fractures when subjected to cyclic loads, delivering joint integrity that lasts through vibration-prone conditions. Its adept handling of heat input yields uniform penetration, so weld profiles exhibit crisp ripples free from undercutting, even when technicians navigate curved or tubular geometries.

Beyond material prowess, holistic service elevates the sourcing experience. Clients benefit from personalized consultations on diameter selection and handling guidance tailored to each application’s demands. Protective packaging shields each spool during transit, and clear labels simplify stock management. Responsive support channels ensure that questions receive prompt replies, turning what could be a tedious purchase process into a collaborative exchange that builds confidence at every turn.

Ergonomic considerations extend to transport and storage. Compact reels nest neatly on workshop racks or vehicle shelves, and lightweight construction eases manual handling. Integrated gripping points enable one-handed lifts when technicians navigate tight spaces, and secure containers keep rods pristine until ready for use. These nuanced touches streamline logistics, helping crews move swiftly between jobs and maintain momentum on demanding schedules.

Environmental stewardship shapes every phase of production. Facilities utilize closed-loop water management and eco-friendly coatings to reduce waste output without sacrificing rod performance. Recyclable spool materials align with green procurement mandates, supporting organizational goals for resource conservation and responsible sourcing. By partnering with forward-thinking suppliers, procurement leads underscore their commitment to both quality and planetary welfare.

Rigorous inspections validate each batch before release. Multi-stage checks confirm alloy consistency and tensile thresholds, while simulated trials under varied thermal conditions ensure rods respond predictably in confined bays or exposed sites. Traceable records facilitate quick issue resolution should any discrepancy arise, reinforcing trust in every delivery. This dedication to precision empowers fabricators to tackle complex challenges with assured craftsmanship.

Imagine equipping your next venture with a filament that combines mechanical excellence, ergonomic design and eco-minded credentials. From streamlined feed reliability to expert guidance and sustainable production, this solution addresses modern demands without compromise. Discover how Aluminum Welding Wire ER5183 can elevate your assemblies and support innovation across evolving sectors by exploring our catalog at www.kunliwelding.com .