In the realm of industrial maintenance and quality control, industrial endoscopes—also known as borescopes—play a crucial role in enabling non-destructive inspection (NDI) of hard-to-reach areas. From inspecting jet engines and turbines to plumbing, pipelines, and automotive cylinders, these specialized visual inspection tools allow engineers and technicians to “see inside” machinery without disassembly, minimizing downtime and maximizing efficiency.

?️ What Is an Industrial Endoscope?

An industrial endoscope is a flexible or rigid optical inspection device that includes:

A camera or optical lens at the tip,

A flexible or rigid probe,

A light source (usually LED),

A monitor or viewer to display real-time visuals.

The endoscope is inserted into tight or enclosed spaces through small access points, allowing high-resolution visual inspection of internal components, welds, corrosion, cracks, or blockages.

? Types of Industrial Endoscopes

Rigid Endoscope

Straight, durable probes for high-resolution inspection in linear paths (e.g., metal casting).

Flexible Endoscope

Bendable probes ideal for curved or complex paths, such as pipes and engines.

Video Borescope (Digital Endoscope)

Equipped with mini cameras and video output; often includes recording and zoom features.

Fiber Optic Borescope

Uses fiber bundles to transmit images to an eyepiece; older but still used for high-temperature or explosive environments.

Articulating Borescope

Allows the tip to be steered in multiple directions using joystick control—ideal for precision inspections.

? Key Features

? High-definition imaging (HD, 1080p, and even 4K)

? Integrated LED lighting

? 360° articulation or tip rotation

? Recording and image capture

? Wi-Fi/Bluetooth connectivity for mobile devices

? Waterproof and explosion-proof designs for hazardous environments

? Various insertion tube lengths (typically 1–10+ meters)

⚙️ Common Applications

✈️ Aerospace & Aviation

Internal inspection of jet engines, turbines, fuel lines, and fuselage components.

? Automotive

Diagnosis of engine cylinders, valves, and exhaust systems without dismantling.

? Industrial Equipment

Inspection of heat exchangers, boilers, and gearboxes in factories and power plants.

? Welding & Manufacturing

Quality control for weld integrity in pipelines, pressure vessels, and structural parts.

?️ Oil & Gas

Pipeline corrosion, blockage, and crack inspection in harsh offshore or onshore environments.

? Plumbing & HVAC

Used by technicians to inspect ducts, drains, vents, and inner pipework.

✅ Benefits of Industrial Endoscopes

? Non-Destructive Testing (NDT): View internals without taking systems apart.

⏱️ Time & Cost Savings: Reduces downtime and expensive teardown procedures.

? Preventive Maintenance: Detect early signs of wear, corrosion, or damage.

? Portability: Compact, handheld units can be used in the field or on-site.

? Documentation: Image/video capture for inspection reports, audits, and regulatory compliance.

? Market Outlook

The industrial endoscope market is growing steadily as industries increasingly adopt predictive maintenance and condition monitoring technologies.

? Market Snapshot:

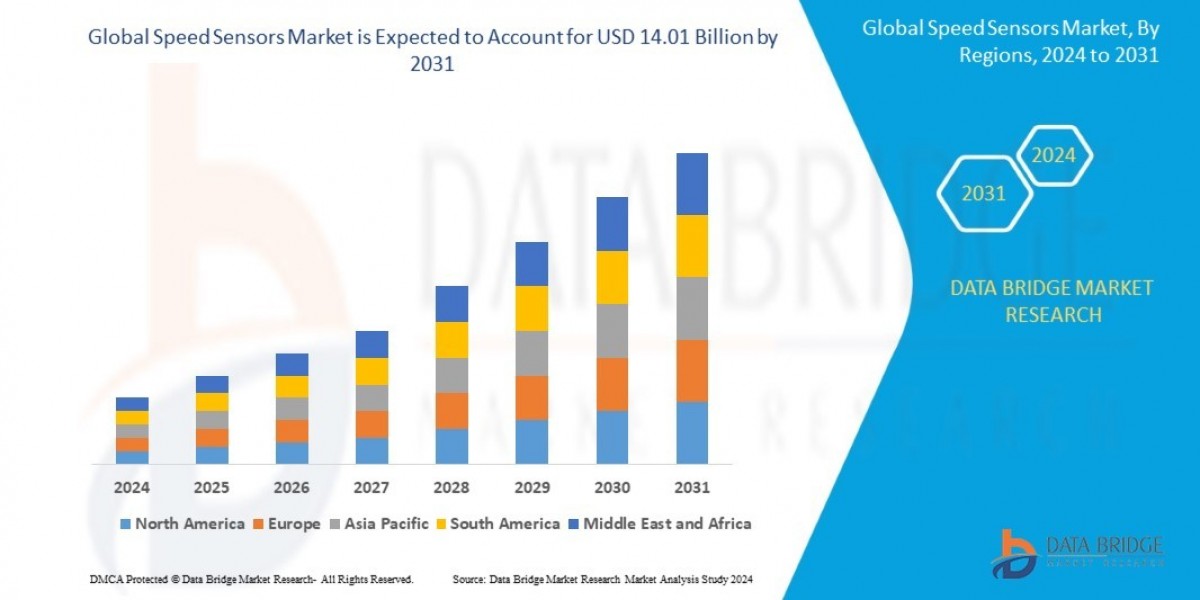

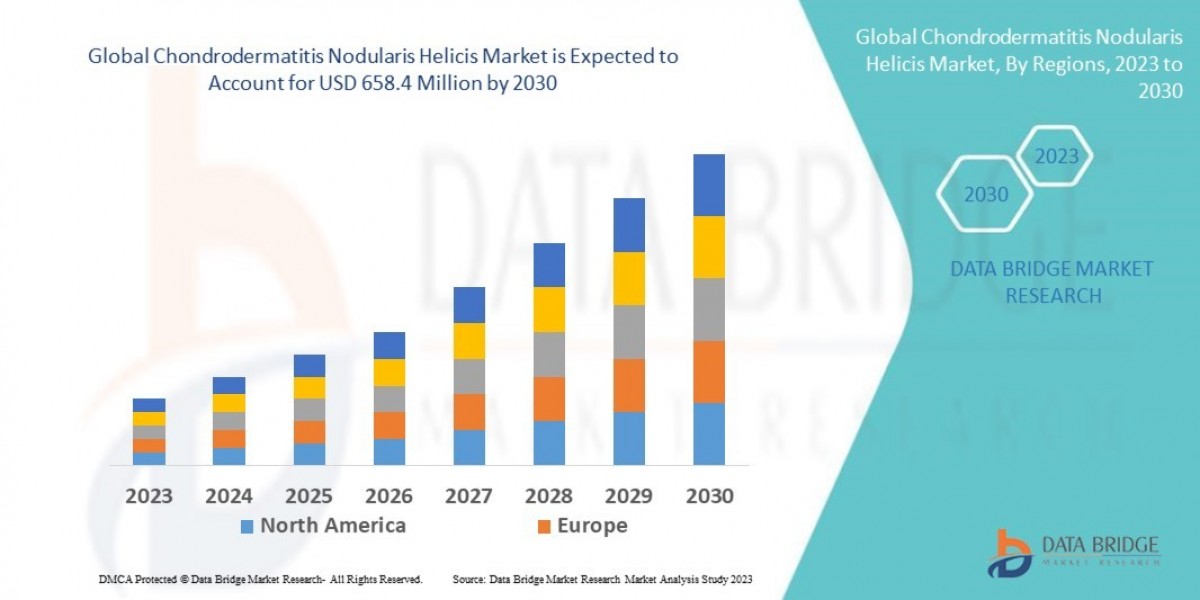

Market Size (2023): ~$800 million–$1 billion

Forecast (2032): ~$2.2–2.5 billion

CAGR (2024–2032): ~10–12%

? Market Drivers:

Increasing demand for asset reliability and uptime

Growth in aerospace, automotive, and oil & gas industries

Rising use of robotic and remote inspection tools

Technological advances in miniaturization and optics

? Key Players

Olympus Corporation

GE Inspection Technologies (Waygate Technologies)

SKF Group

Fluke Corporation

PCE Instruments

Stryker (Industrial Applications)

Yateks

Mitcorp

Karl Storz (Industrial Division)

? Future Trends

AI-assisted defect recognition

Cloud-based inspection data management

3D imaging and depth mapping

Integration with robotic crawlers and drones

Explosion-proof and high-temperature models

? Conclusion

Industrial endoscopes are vital tools for modern inspection and maintenance, offering a clear view into complex systems without the cost or time of disassembly. Whether you're maintaining aircraft engines, inspecting pipeline welds, or troubleshooting factory machines, an endoscope delivers efficiency, precision, and safety.

As industries become smarter and more automated, the role of intelligent, connected inspection tools like industrial endoscopes will continue to expand—helping businesses protect assets, ensure compliance, and stay ahead of failures.

Wantstats is a premium platform that provides unparalleled data and statistics across 30000 markets and 100 countries in both B2B and B2C segments. Designed to fit the needs of industry stakeholders, associations, libraries, students and many more looking for statistics.

Read More