The Industry Controls and Factory Automation Market is experiencing transformative growth, driven by the global demand for smarter, safer, and more efficient manufacturing systems. As industrial sectors embrace digital transformation, automation technologies are becoming the backbone of modern production strategies.

Market Overview

Valued at over USD 130 billion in 2024, the Industry Controls and Factory Automation Market is projected to expand at a CAGR of 8–10% through 2030. This surge is powered by the convergence of operational technology (OT) and information technology (IT), and the integration of next-generation systems like artificial intelligence (AI), Internet of Things (IoT), and robotics.

What Is Industry Control and Factory Automation?

Industry controls and automation refer to the use of advanced control systems—including distributed control systems (DCS), programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA), and human-machine interfaces (HMI)—to manage machinery, production lines, and entire plants. These technologies reduce human intervention, improve efficiency, minimize downtime, and enhance product quality and safety.

Key Market Drivers

Industry 4.0 and Digital Transformation

The fourth industrial revolution is built on automation, smart manufacturing, and real-time data analytics, all of which require robust industrial control systems.Demand for Operational Efficiency

Manufacturing firms seek to reduce waste, improve energy use, and boost production uptime. Automation solutions enable predictive maintenance, better inventory management, and real-time decision-making.Growth of the Smart Factory Concept

Smart factories leverage IoT sensors, digital twins, and AI to optimize workflows. This trend is encouraging large-scale adoption of automated systems across industries.Labor Shortages and Safety Concerns

Automation helps address workforce gaps while reducing workplace hazards in high-risk environments such as oil & gas, chemicals, and heavy manufacturing.Sustainability and Energy Management

Modern control systems enable detailed monitoring and control of energy consumption, contributing to greener manufacturing processes and regulatory compliance.

Core Technologies and Components

PLC & SCADA Systems for centralized and decentralized process control

DCS for managing complex industrial processes in industries like oil & gas and power generation

Industrial Sensors for real-time data acquisition

Machine Vision Systems for quality inspection and measurement

Robotics including robotic arms and autonomous mobile robots

Industrial Networking & IIoT Platforms for data integration and connectivity

Industry Applications

Automotive: Robotic welding, assembly line automation

Food & Beverage: Sanitation-compliant automated handling

Energy & Utilities: Grid management, substation automation

Healthcare: Pharmaceutical production and quality control

Aerospace & Defense: Precision component manufacturing

Regional Insights

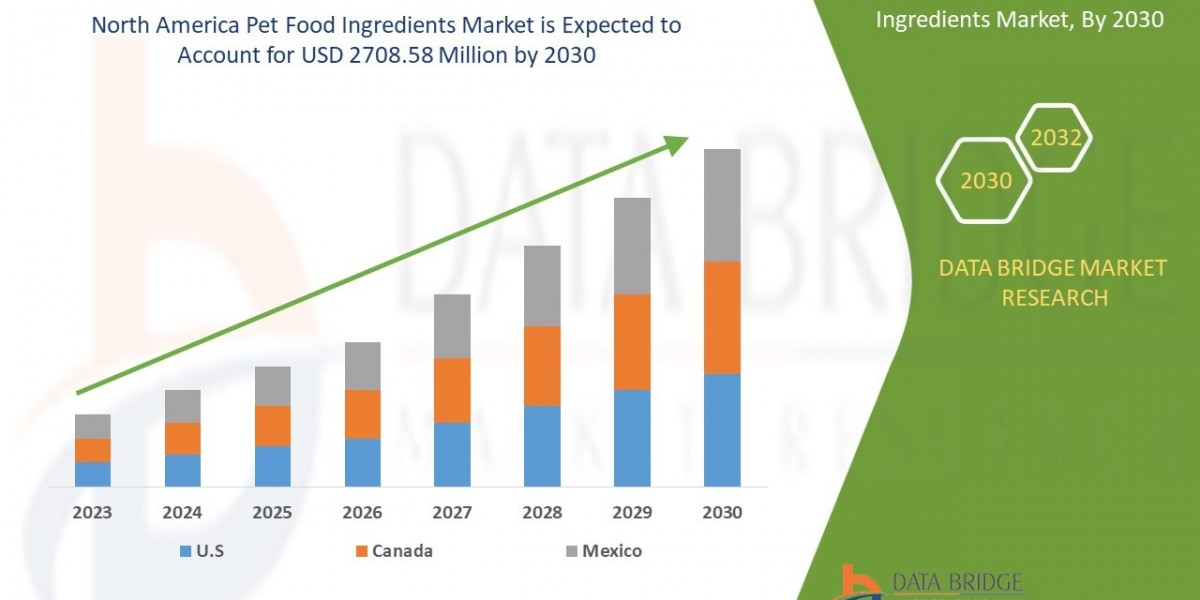

North America leads in adoption due to a strong industrial base and investments in smart manufacturing.

Europe focuses on energy efficiency and sustainability through automation.

Asia-Pacific is the fastest-growing market, especially in China, India, and Southeast Asia, driven by government-led digitization and expanding industrial output.

Key Players in the Market

Prominent players shaping the Industry Controls and Factory Automation Market include:

Siemens AG

Rockwell Automation

ABB Ltd.

Schneider Electric

Emerson Electric

Honeywell International

Mitsubishi Electric

General Electric

Yokogawa Electric Corporation

These companies are focused on offering end-to-end automation solutions, often backed by AI, cloud computing, and advanced analytics.

Market Challenges

High Capital Investment: Implementation requires significant upfront cost and skilled personnel.

System Integration Complexity: Legacy systems often require custom integration and security enhancements.

Cybersecurity Threats: As connectivity increases, so do risks of industrial cyber-attacks.

Future Outlook

The Industry Controls and Factory Automation Market will continue to evolve, with emerging trends including edge computing, AI-driven process optimization, 5G-based industrial communication, and fully autonomous factory operations. These advancements are expected to redefine productivity and flexibility in manufacturing worldwide.

Conclusion

The shift toward intelligent, automated, and connected factories is irreversible. The Industry Controls and Factory Automation Market is not only helping businesses streamline operations and reduce costs, but also enabling them to build resilient, adaptive, and environmentally responsible supply chains. Companies investing in automation today are positioning themselves for long-term leadership in the industrial economy of tomorrow.

read more

| UK Mechanical Keyboard Market |

| Canada Metrology Market |

| France Metrology Market |

| Germany Metrology Market |

| Italy Metrology Market |