Force & Torque Sensor Market: Powering Precision in Automation and Robotics

The global Force & Torque Sensor Market is experiencing significant growth as industries increasingly rely on precision sensing for automation, quality control, and robotics. These sensors, which measure force, load, pressure, and torque, play a critical role in industrial automation, medical devices, aerospace, automotive, and consumer electronics.

Market Overview

The Force & Torque Sensor Market has witnessed robust growth over recent years, propelled by increasing demand for smart manufacturing and industrial automation. These sensors enable real-time data collection and feedback, leading to enhanced efficiency, quality assurance, and safety in production environments.

Market Size (2024): Estimated at USD XX billion

Projected Market Size (2032): Expected to reach USD XX billion

Forecast Period: 2024–2032

Compound Annual Growth Rate (CAGR): Around X.X%

(Note: Replace XX with accurate figures if available.)

Key Market Drivers

1. Rise of Industrial Automation and Industry 4.0

As factories move toward automation and smart manufacturing, force and torque sensors become vital components in robotic arms, CNC machines, and assembly lines. These sensors help detect force feedback, ensuring accurate performance in delicate and high-precision tasks.

2. Growth in the Robotics Sector

In collaborative robotics (cobots) and autonomous machines, force and torque sensors help robots interact safely with humans and handle objects delicately. As the adoption of robotics grows in manufacturing, healthcare, and logistics, so does the demand for these sensors.

3. Demand in Medical Applications

In the medical sector, force sensors are used in surgical robots, rehabilitation equipment, and prosthetics. These applications require highly sensitive and accurate sensors for patient safety and effective operation.

4. Automotive Innovations

Torque sensors are essential for electric power steering (EPS), transmission systems, and electric motors in vehicles. The rise of electric vehicles (EVs) and autonomous driving technologies further boosts the need for real-time torque monitoring.

5. Aerospace and Defense Requirements

In aerospace, force and torque sensors are used for component testing, flight control systems, and structural health monitoring. High reliability and safety standards in the sector make sensor performance crucial.

Market Segmentation

• By Type

Force Sensors (Load Cells, Strain Gauges, etc.)

Torque Sensors (Rotary, Reaction, etc.)

• By Application

Industrial Automation

Robotics

Medical Devices

Automotive

Aerospace & Defense

Consumer Electronics

• By End-Use Industry

Manufacturing

Healthcare

Transportation

Research & Development

Energy

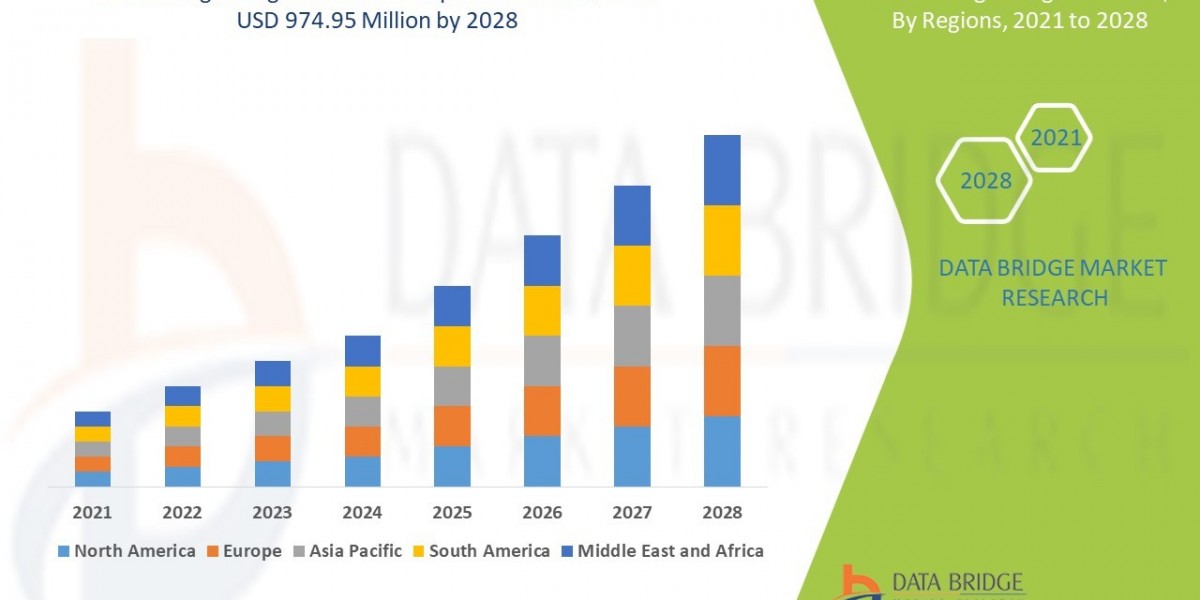

Regional Insights

• North America

A leader in robotics, automation, and medical technology, North America is a key contributor to market growth.

• Europe

Europe’s focus on advanced manufacturing, automotive innovation, and renewable energy solutions supports sensor adoption.

• Asia-Pacific

Home to rapidly growing economies like China, Japan, and South Korea, the region is seeing high demand for sensors in electronics and automotive production.

• Rest of the World

Countries in Latin America and the Middle East are gradually adopting automation technologies, creating new growth opportunities.

Emerging Trends

Miniaturization of Sensors: Compact, lightweight sensors for wearables and micro-robotics.

Wireless Force/Torque Sensors: For applications in remote monitoring and mobile robotics.

Integration with AI & IoT: Enabling real-time data analytics, predictive maintenance, and smart feedback loops.

Advanced Materials: Use of MEMS and flexible electronics for higher durability and sensitivity.

Challenges

High Cost: Advanced force/torque sensors can be expensive, limiting adoption among small and medium enterprises.

Calibration & Maintenance: Ensuring accuracy over time requires frequent calibration and careful maintenance.

Standardization: Varying standards across industries and regions can hinder widespread integration.

Competitive Landscape

Key players in the market include:

ATI Industrial Automation

Honeywell International Inc.

FUTEK Advanced Sensor Technology, Inc.

Hottinger Brüel & Kjær (HBK)

Kistler Group

ABB Ltd.

TE Connectivity

These companies focus on R&D, innovation in sensor materials, and industry-specific solutions to gain market share.

Conclusion

The Force & Torque Sensor Market is poised for strong growth, fueled by the demand for smarter, safer, and more precise systems across industries. As digital transformation accelerates globally, the role of these sensors becomes increasingly critical in enabling real-time control, predictive maintenance, and human-machine collaboration.

Read More

| Robot Teach Pendant Market |

| Wi-Fi Based Smart Locks Market |

| Wind Turbine Condition Monitoring Market |

| Semiconductor Gas Filters Market |

| Low Light Imaging Market |

| Magnetic Connector Market |