The global Heat Treatment Furnace Market was valued at US$ 11590 million in 2024 and is anticipated to reach US$ 12930 million by 2031, witnessing a CAGR of 1.6% during the forecast period 2025-2031.

Heat Treatment is the process in which metallic/steel parts are exposed completely or partially to time-temperature sequences in order to change the mechanical and/or corrosion properties.

Academically, Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material.

Request For Sample Link: https://www.qyresearch.in/request-sample/machinery-equipment-global-heat-treatment-furnace-market-insights-industry-share-sales-projections-and-demand-outlook-2025-2031

The Heat Treatment Furnace is those furnaces used in the process of hear treatment.

For industry structure analysis, the Heat Treatment Furnace industry is not concentrated. These manufacturers range from large multinational corporations to small privately owned companies compete in this industry. The top five producers include Andritz, Tenova, Primetals Technologies, Aichelin Group and Inductotherm Corporation, account for about 10 % of the revenue market. Regionally, Europe is the biggest production value area, also the leader in the whole Heat Treatment Furnace industry.

Europe occupied 28% of the production market. It is followed by North America and China, which respectively account for around 26% and 26% of the global total industry. Other countries have a smaller amount of production. Geographically, Europe was the largest consumption market in the world, which took about 26% of the global consumption volume.

What Is a Heat Treatment Furnace?

A heat treatment furnace is an industrial device used to heat materials—primarily metals and alloys—to specific temperatures for processes such as annealing, quenching, tempering, and hardening. These furnaces are vital for altering the microstructure and physical properties of components, ensuring they meet the demands of high-performance applications.

Key Market Drivers

- Rising Demand from the Automotive Industry

Heat treatment is crucial for manufacturing components such as gears, crankshafts, and axles. With the growing production of electric and fuel-based vehicles, the need for advanced furnace systems is escalating. - Infrastructure Development and Metallurgical Processes

The expansion of railways, construction activities, and metal fabrication industries, especially in Asia-Pacific and the Middle East, is boosting demand for heat treatment equipment. - Energy Efficiency and Technological Advancements

Modern furnaces are designed for reduced energy consumption and enhanced process control. The integration of smart controls, automation, and IoT in furnace systems is contributing to market growth. - Aerospace and Defense Applications

High-precision heat treatment is essential for producing lightweight, high-strength components used in aircraft, spacecraft, and defense vehicles. These industries are adopting advanced vacuum and controlled atmosphere furnaces.

Market Segmentation

- By Type:

- Electric Heat Treatment Furnace

- Gas-fired Heat Treatment Furnace

- Vacuum Furnace

- Induction Furnace

- Others

- By Application:

- Automotive

- Aerospace

- Metal & Steel Industry

- Construction

- Others (Energy, Electronics, Tools Manufacturing)

- By Region:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Regional Insights

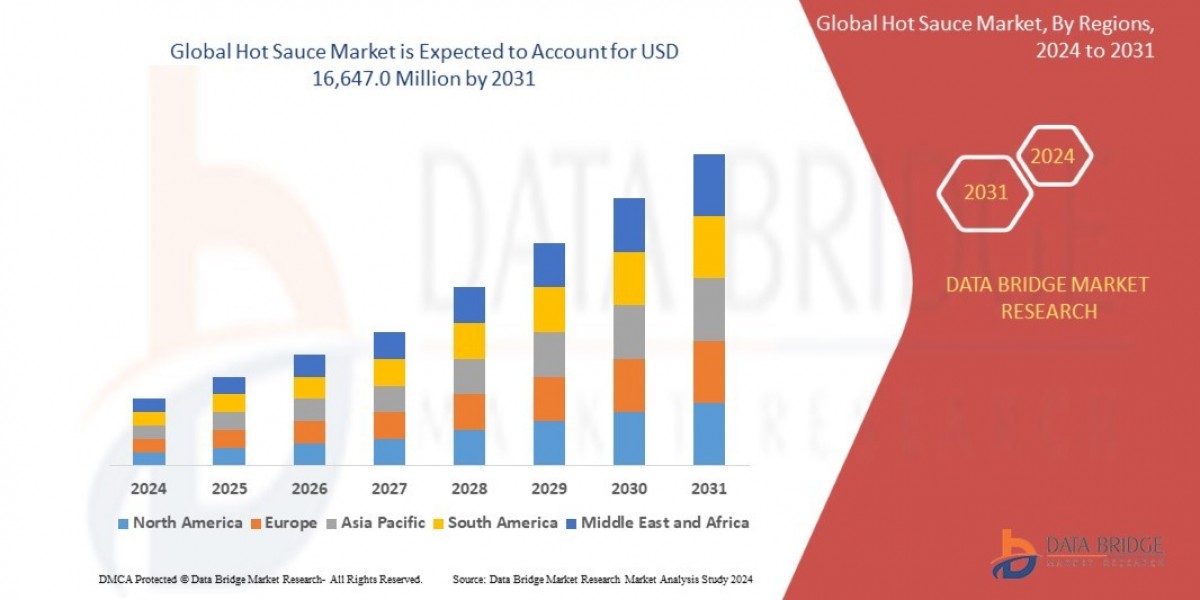

Asia-Pacific holds the largest share of the global heat treatment furnace market, led by countries like China, India, and Japan. This is due to rapid industrial growth, a strong steel industry, and government investments in infrastructure.

North America follows, with significant contributions from aerospace, defense, and automotive sectors in the U.S. and Canada.

Europe remains a vital market with a strong focus on energy-efficient and environmentally friendly industrial heating technologies.

Key Players

Prominent companies operating in the Heat Treatment Furnace Market include:

- Tenova S.p.A.

- ThermProcess

- ALD Vacuum Technologies GmbH

- Lindberg/MPH

- SECO/WARWICK

- Carbolite Gero

- Ipsen International GmbH

- Nutec Bickley

- Cieffe Forni Industriali

- Nachi-Fujikoshi Corp.

These players are investing in R&D to improve energy efficiency, automation, and process flexibility in heat treatment systems.

Future Trends and Opportunities

· Smart Furnaces with real-time monitoring and AI-based process optimization.

· Eco-Friendly Heating Technologies including renewable energy integration.

· Customization and Modular Furnace Systems for small-scale industrial setups.

· Expansion in Emerging Markets due to industrial policy reforms and investments in manufacturing hubs.

Conclusion

The Heat Treatment Furnace Market is positioned for robust growth as industries evolve and demand high-performance materials. With advancements in automation, energy optimization, and digital control, heat treatment technology is becoming more precise, efficient, and eco-conscious. Manufacturers and suppliers who innovate in energy savings and intelligent control will be at the forefront of this evolving landscape.

About Us:

QY Research established in 2007, focus on custom research, management consulting, IPO consulting, industry chain research, data base and seminar services. The company owned a large basic data base (such as National Bureau of statistics database, Customs import and export database, Industry Association Database etc), expert's resources (included energy automotive chemical medical ICT consumer goods etc.

Contact Us:

QY Research, INC.

315 Work Avenue, Raheja Woods,

Survey No. 222/1, Plot No. 25, 6th Floor,

Kayani Nagar, Yervada, Pune 411006, Maharashtra

Tel: +91-8669986909

Emails - enquiry@qyresearch.in / mohit@qyresearch.com