Flash point testers are indispensable instruments used across numerous industries to measure the lowest temperature at which a volatile liquid will ignite in the presence of an ignition source. This critical measurement, known as the flash point, is a cornerstone of safety protocols, product quality control, and regulatory compliance, particularly when handling flammable and combustible materials. The market for these devices is driven by the universal need to ensure safe handling, storage, and transport of a vast array of chemicals, fuels, and consumer products.

How a Flash Point Tester Works

The fundamental principle behind a flash point tester is to heat a sample of a liquid at a controlled rate and, at specific intervals, introduce an ignition source (like a small flame or electric arc) into the vapor space above the liquid. The flash point is recorded at the precise temperature where a brief flash or "flash-over" occurs, indicating that the concentration of flammable vapors has reached a level sufficient to ignite. The two main types of flash point testers are:

Open-Cup Testers: The sample is heated in an open cup, and the flash point is measured as the vapor mixes with the surrounding air. The Cleveland Open Cup (COC) method is a widely recognized standard for this type of tester.

Closed-Cup Testers: The sample is heated in a sealed cup, and the vapor is contained, creating a more controlled and confined environment. This method typically yields a lower flash point than the open-cup method and is often considered more accurate for safety regulations. The Pensky-Martens and Tag Closed Cup methods are common examples.

Modern flash point testers have evolved from simple manual devices to highly automated, microprocessor-controlled instruments. These automated systems offer superior precision, repeatability, and safety by eliminating human error and ensuring strict adherence to standardized test methods.

Key Applications and Industries

The utility of a flash point tester extends across a wide spectrum of sectors:

Petroleum and Petrochemicals: This is perhaps the largest market for flash point testers. They are used to classify fuels (like diesel, gasoline, and jet fuel), lubricants, and other petroleum products according to their fire hazard. This data is crucial for safe transportation, storage, and quality assurance.

Paints, Coatings, and Inks: Flash point analysis is vital for manufacturers to determine the safe handling and application of these products, which often contain flammable solvents.

Chemicals: The chemical industry relies on flash point testing for raw material analysis, product formulation, and to meet safety data sheet (SDS) requirements for hazardous material classification.

Food and Beverages: Flash point is a key parameter for products containing alcohol, such as certain flavorings and spirits, ensuring safe production and storage.

Pharmaceuticals: In pharmaceutical manufacturing, flash point testing is used to ensure the safety of solvents and other flammable liquids used in production and formulation.

Regulatory Compliance: Governments and international organizations mandate flash point testing for the classification of hazardous materials, influencing everything from shipping regulations to workplace safety standards.

Market Drivers and Trends

The demand for flash point testers is consistently driven by several factors:

Growing Focus on Workplace Safety: Increasing awareness and stricter regulations concerning fire safety in industrial environments are compelling businesses to invest in reliable testing equipment.

Quality Control and Assurance: Manufacturers use flash point analysis as a critical quality control parameter to ensure their products meet specific performance and safety standards.

Technological Advancements: The shift from manual to automated and semi-automated testers is a significant trend. These newer devices offer enhanced user safety, improved accuracy, and reduced testing time.

Global Harmonization of Standards: The adoption of international standards for flash point testing (e.g., ISO, ASTM) is driving the need for instruments that can perform a wide range of standardized tests.

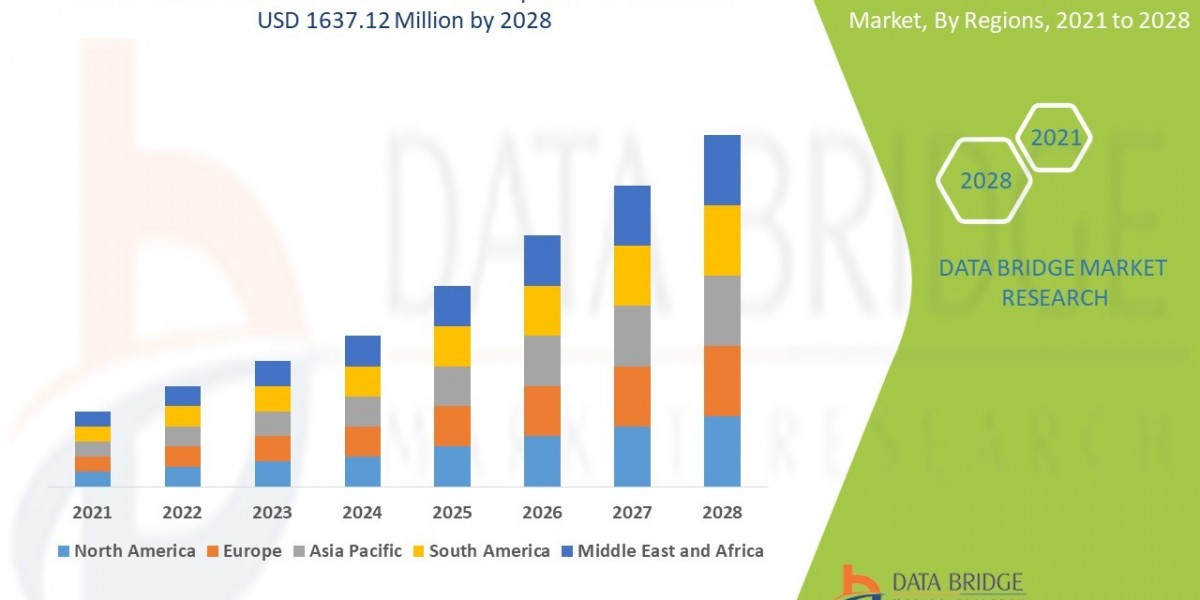

Demand from Emerging Economies: Rapid industrialization in developing countries is leading to a greater emphasis on safety and quality control, thereby increasing the market for testing equipment.

In conclusion, flash point testers are more than just laboratory instruments; they are a fundamental part of the global infrastructure for safety and quality. As industries continue to evolve and as regulatory standards become more stringent, the role of these precision instruments will only become more critical in safeguarding people, products, and the environment.

Related Reports:

Direct Broadcasting Satellite Equipment Market

Electronic Point Of Sale Epo Market

Flexible Electronics And Circuit Market

Free Space Optics Fso Visible Light Communication Vlc Market