The industrial landscape is undergoing a transformative shift, driven by the need for automation that complements, rather than replaces, human workers. Collaborative robots, or cobots, are emerging as key enablers of this new era. Designed to work safely alongside humans, these robots are revolutionizing industries by enhancing productivity, improving safety, and enabling flexible manufacturing processes.

What Are Collaborative Robots?

Collaborative robots are robotic systems designed to work directly with human operators in a shared workspace. Unlike traditional industrial robots that require physical barriers, cobots are equipped with advanced sensors, safety mechanisms, and user-friendly interfaces that ensure secure and intuitive interaction with human counterparts.

Key Market Drivers

Growing Demand for Automation Across SMEs: Cobots offer an affordable entry point into automation for small and medium enterprises.

Increased Workplace Safety and Ergonomics: They reduce repetitive strain injuries and perform hazardous tasks, improving worker safety.

Ease of Integration and Programming: Modern cobots are easy to deploy and reprogram, reducing downtime and boosting ROI.

Labor Shortages and Rising Wages: Many industries are turning to cobots to supplement human labor amid skill shortages.

Major Applications

Automotive and electronics assembly

Food and beverage packaging

Pharmaceutical handling

Metalworking and welding

Quality inspection and testing

Market Outlook to 2030

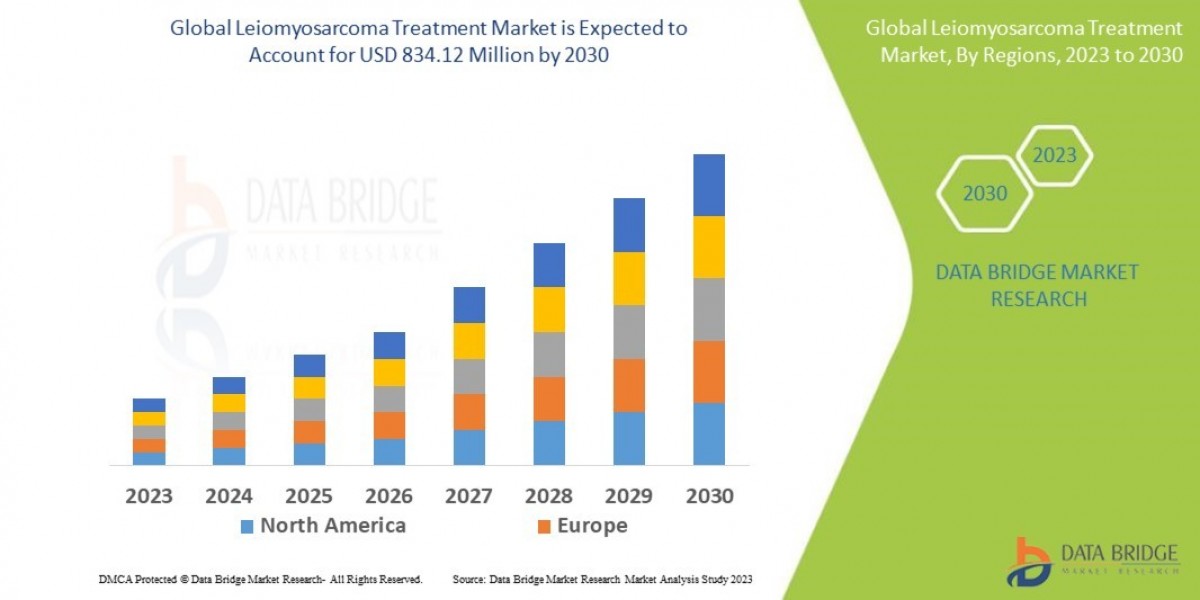

The global Collaborative Robots Market is projected to grow at a significant compound annual growth rate (CAGR) through 2030. Growth is expected to be fueled by increasing investments in Industry 4.0, demand for flexible automation, and the adoption of AI-enhanced cobots. Key regions leading the market include North America, Europe, and the rapidly expanding Asia-Pacific.

Read More